Dübel deliği delme makinesiGanner

DB 21

Dübel deliği delme makinesi

Ganner

DB 21

Üretim yılı

2024

Durumu

Kullanılmış

Konum

Nattheim

Resimleri göster

Haritayı göster

Makineye ait bilgiler

- Makine tanımı:

- Dübel deliği delme makinesi

- Makine üreticisi:

- Ganner

- Model:

- DB 21

- Üretim yılı:

- 2024

- Durumu:

- kullanılmış

Fiyat ve Konum

- Konum:

- Daimlerstr. 21, 89564 Nattheim, DE

Ara

Teklif detayları

- Listeleme kimliği:

- A20292745

- Referans no.:

- BD-P-24005

- Son güncelleme tarihi:

- 24.01.2026

Açıklama

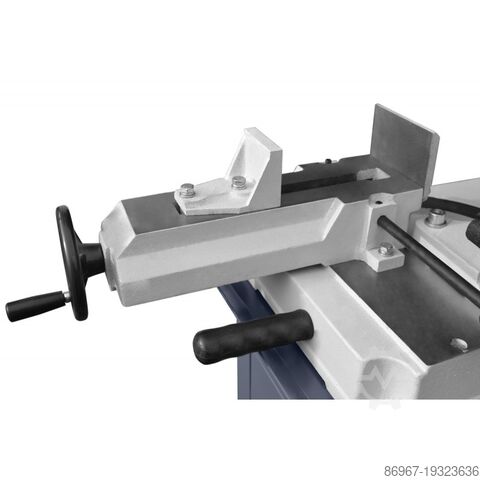

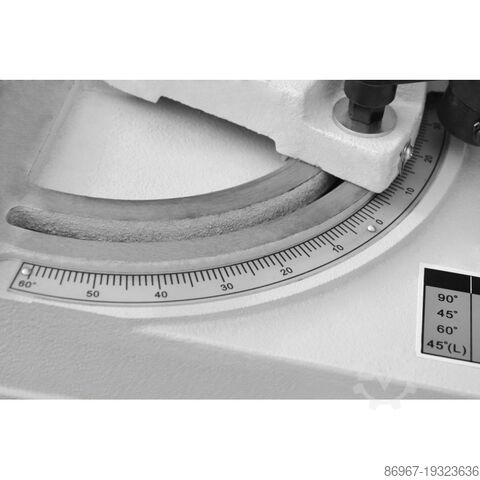

Dowel Hole Drilling Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW Complete in standard configuration with: - Fully automatic electronic control with impulse operation via foot pedal for clamping-drilling-unclamping, with electrical skip drilling functionality. - Automatic return of the drilling unit after reaching the set drilling depth. - Automatic extension of drilling depth for end-grain drilling, eliminating the need to reset drilling depth when switching from flat face to end grain (e.g., +10 mm for dowel length 35 mm, flat face drilling depth 14 mm, end grain drilling depth 24 mm). - 1 drilling beam with 21 spindles, 32 mm spindle pitch, 1.5 kW motor (drill feed 0-70 mm). Includes 21 quick-change chucks (Ganner system) for easy drill bit replacement. - Easy pivoting of the drill unit from 0° to 90°, assisted by gas cylinder. - 1 clamp carrier, movable along the Y-axis with 3 pneumatic clamping cylinders, suitable for workpiece heights up to max. 80 mm.

Lsdpfx Aajxnlflsfjhb

Ideal stop system, consisting of: - 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 locating stops, with quick-change system, easily switchable from right to left stop side for mirrored shelf drilling in cabinet construction, also usable for line boring in System 32. - Side stops and position adjustments including the setting of drilling height via mechanical digital counters on the support table. - Side stops can be easily swung away for shortest possible changeover from cabinet drilling to frame and line drilling operations. - Clamping arms for the clamp carrier designed for row positions up to max. 300 mm. - Optimal three-stage tool system.

1 set of dowel drill bits: - 5 carbide-tipped dowel bits, Ø 8x77 mm, right-cutting - 4 carbide-tipped dowel bits, Ø 8x77 mm, left-cutting

Base machine Dowel Hole Drilling Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW Complete in standard configuration with: - Fully automatic electronic control with impulse operation via foot pedal for clamping-drilling-unclamping, with electrical skip drilling functionality. - Automatic return of the drilling unit after reaching the set drilling depth. - Automatic extension of drilling depth for end-grain drilling, eliminating the need to reset drilling depth when switching from flat face to end grain (e.g., +10 mm for dowel length 35 mm, flat face drilling depth 14 mm, end grain drilling depth 24 mm). - 1 drilling beam with 21 spindles, 32 mm spindle pitch, 1.5 kW motor (drill feed 0-70 mm). Includes 21 quick-change chucks (Ganner system) for easy drill bit replacement. - Easy pivoting of the drill unit from 0° to 90°, assisted by gas cylinder. - 1 clamp carrier, movable along the Y-axis with 3 pneumatic clamping cylinders, suitable for workpiece heights up to max. 80 mm.

Ideal stop system, consisting of: - 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 locating stops, with quick-change system, easily switchable from right to left stop side for mirrored shelf drilling in cabinet construction, and also applicable for line boring using System 32. - Side stops and position adjustments including adjustment of the drilling height via the support table using mechanical digital counters. - Side stops can be easily swung away for shortest possible conversion between cabinet, frame, and line boring operations. - Clamping arms for the clamp carrier designed for row positions up to max. 300 mm. - Ideal three-stage tool system.

Extraction funnel, dust tes

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Lsdpfx Aajxnlflsfjhb

Ideal stop system, consisting of: - 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 locating stops, with quick-change system, easily switchable from right to left stop side for mirrored shelf drilling in cabinet construction, also usable for line boring in System 32. - Side stops and position adjustments including the setting of drilling height via mechanical digital counters on the support table. - Side stops can be easily swung away for shortest possible changeover from cabinet drilling to frame and line drilling operations. - Clamping arms for the clamp carrier designed for row positions up to max. 300 mm. - Optimal three-stage tool system.

1 set of dowel drill bits: - 5 carbide-tipped dowel bits, Ø 8x77 mm, right-cutting - 4 carbide-tipped dowel bits, Ø 8x77 mm, left-cutting

Base machine Dowel Hole Drilling Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW Complete in standard configuration with: - Fully automatic electronic control with impulse operation via foot pedal for clamping-drilling-unclamping, with electrical skip drilling functionality. - Automatic return of the drilling unit after reaching the set drilling depth. - Automatic extension of drilling depth for end-grain drilling, eliminating the need to reset drilling depth when switching from flat face to end grain (e.g., +10 mm for dowel length 35 mm, flat face drilling depth 14 mm, end grain drilling depth 24 mm). - 1 drilling beam with 21 spindles, 32 mm spindle pitch, 1.5 kW motor (drill feed 0-70 mm). Includes 21 quick-change chucks (Ganner system) for easy drill bit replacement. - Easy pivoting of the drill unit from 0° to 90°, assisted by gas cylinder. - 1 clamp carrier, movable along the Y-axis with 3 pneumatic clamping cylinders, suitable for workpiece heights up to max. 80 mm.

Ideal stop system, consisting of: - 1 stop rail, 1800 mm, for shelf drilling (aluminum profile 40x40 mm) with 3 locating stops, with quick-change system, easily switchable from right to left stop side for mirrored shelf drilling in cabinet construction, and also applicable for line boring using System 32. - Side stops and position adjustments including adjustment of the drilling height via the support table using mechanical digital counters. - Side stops can be easily swung away for shortest possible conversion between cabinet, frame, and line boring operations. - Clamping arms for the clamp carrier designed for row positions up to max. 300 mm. - Ideal three-stage tool system.

Extraction funnel, dust tes

Bu ilan otomatik olarak tercüme edildiğinden bazı çeviri hataları oluşmuş olabilir.

Tedarikçi

Not: Ücretsiz kaydolun veya giriş yapın, tüm bilgilere erişmek için.

İlk kayıt tarihi: 2010

İstek gönder

Telefon & Faks

+49 7321 ... ilanlar

Bu ilanlar da ilginizi çekebilir.

Küçük ilan

Siedlce

Siedlce

1.776 km

Bant testere

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Küçük ilan

Bad Sooden-Allendorf

Bad Sooden-Allendorf

2.392 km

Dübel makinesi

ScheerDB 150

ScheerDB 150

Küçük ilan

Juszczyn

Juszczyn

1.714 km

Çok milli delme makinesi

MaggiBoring System 35

MaggiBoring System 35

Küçük ilan

Certaldo

Certaldo

2.083 km

çok milli delme makinesi

Maggi EngineeringBoring System 800 GT

Maggi EngineeringBoring System 800 GT

Küçük ilan

Nordhorn

Nordhorn

2.624 km

Sunta Zemin kaplaması Depolama platformu Panosu

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

Küçük ilan

Berlin

Berlin

2.254 km

Tam koruma ve daha yüksek güvenlik.

Bodori5 3000W

Bodori5 3000W

Küçük ilan

Bad Sooden-Allendorf

Bad Sooden-Allendorf

2.392 km

Kenar bantlama makinesi

BMS - BlaichKantenfix B2

BMS - BlaichKantenfix B2

Küçük ilan

Wijchen

Wijchen

2.685 km

Briket Presi Schuko Compacto CT 700 S-20 2017

SchukoCompacto CT 700 S-20

SchukoCompacto CT 700 S-20

Küçük ilan

Siedlce

Siedlce

1.776 km

Kenar taşlama

CORMAKMM2315Q 400/230V

CORMAKMM2315Q 400/230V

Küçük ilan

Karsin

Karsin

2.116 km

Vitap Alfa 21 çok milli delme makinesi

Vitapalfa 21r

Vitapalfa 21r

İlanınız başarıyla silindi

Bir hata oluştu